What kind of Extruder?

An Extruder is not just an Extruder, and most importantly, “any” extruder is not capable of doing “any” kind of extrusion job. Extruders are designed to do specific jobs effectively and efficiently. Some are more flexible than others, but still, there is no single design capable of covering the entire range of Extrusion Applications we are facing today.

“any” kind of extrusion job. Extruders are designed to do specific jobs effectively and efficiently. Some are more flexible than others, but still, there is no single design capable of covering the entire range of Extrusion Applications we are facing today.

Looking at the list of potential Food and Feed products we discussed before again, and it is easy to understand that a wide range of different ingredients will be required to manufacture these individual products.

These ingredients all have different Physical and Food-chemical characteristics. For example, some are high in Fat content and low in Protein, while others have low levels of Fat and high levels of Protein, and so forth. This varying-ingredient-characteristic situation requires Extrusion Operating Conditions controlled to specific levels in order to successfully add value to the ingredients or formulations we are processing.

It is therefore of utmost importance to carefully consider the following before making a decision to invest in an extruder:

- What are the ingredients or formulations to be extruded?

- What are the End Products (and their desired characteristics) we wish to produce by means of Extrusion?

- Are there any Anti-Nutritional Factors to be dealt with?

- Are there any physical characteristics we need to provide to the final product? Examples may include

- Buoyancy in the case of Floating, Slow-Sinking or Sinking Aquatic Feeds

- Texture in the case of TVP (Textured Vegetable Protein) and TSP (Textured Soy Protein)

- Shape and Size in the case of Aquatic Feeds, Petfoods, some Animal Feeds, Snack Foods or RTE Breakfast Cereals.

- “Mouth Feel” in the case of RTE Breakfast Cereals and Snack Foods

hp dezign can assist with Business Modelling and Feasibility Studies helping customers to make sure they make the correct Extrusion Decision.

The following discussion briefly describes typical applications. Please contact hp dezign should you need to discuss your specific aspirations in more detail.

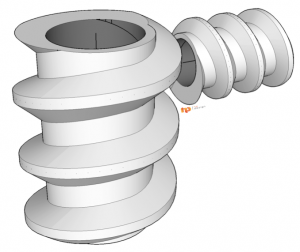

Medium Shear Extrusion

Medium Shear Extrusion is the preferred technology for producing Feed and Food products that (apart from nutritional requirements) require specific physical characteristics (shape, size, texture, mouth-feel, etc). Typical applications are:

- Aquatic Feeds – aquatic feeds have very high manufacturing requirements and rely on Medium Shear Extruders for making feeds where

- impact on the environment is kept to a minimum;

- water stability of feeds is maximised

- a range of shapes and sizes are possible meeting specific species requirements

- buoyancy of feeds could be controlled though the extrusion process

- Petfoods – pet owners place very high demand on physical characteristics of Petfoods such as shape, size, colour and palatability. Medium Shear Extrusion is the choice of technology when producing high quality petfoods.

- Shaped Animal Feeds – making shaped feeds for farm animals have fewer demands compared to Aquatic Feeds and Petfoods. Pig Starter Feed is a good example of a Shaped Animal Feed manufactured through extrusion. The advantages of early weaning of piglets and economic impact on commercial piggeries is well documented.